Ceramic Green Strength

Quick Start

The green strength of a ceramic/binder system can be estimated from just a few parameters. The choice of the binder polymer and the effect of "small" amounts of additive can be significant.

Particle Adhesion

When you make a ceramic you have, in essence, a volume fraction εs of the solid ceramic and a volume fraction εb of binder, with the remainder being voids. The binder will have an inherent yield strength σyield and we will assume that it has perfect adhesion to the particles, so that failure in the green ceramic is within the binder rather than at the interface.

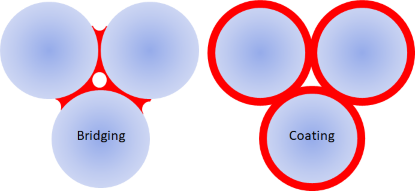

Under this simple scenario, how does the green strength, measured as a yield strength σ, depend on the fractions of ceramic, φc and binder, φb (and therefore on the void fraction, φv? A paper by the Lombardo group1 gives us two answers depending on how the binder interacts with the powder. If it bridges the particles then the binder is "focussed" on a few critical spots and the relative strength is high. If it coats the particles then the binder is spread rather uselessly around much of the particle, so the relative strength is less. This has a profound impact on one's design philosophy for particle-binder wetting. Too little and the binder is useless, too much and it is wasted as coating, with probably other downsides caused by the excess binder (you have to add more to get the strength) during the thermal removal process.

Under this simple scenario, how does the green strength, measured as a yield strength σ, depend on the fractions of ceramic, φc and binder, φb (and therefore on the void fraction, φv? A paper by the Lombardo group1 gives us two answers depending on how the binder interacts with the powder. If it bridges the particles then the binder is "focussed" on a few critical spots and the relative strength is high. If it coats the particles then the binder is spread rather uselessly around much of the particle, so the relative strength is less. This has a profound impact on one's design philosophy for particle-binder wetting. Too little and the binder is useless, too much and it is wasted as coating, with probably other downsides caused by the excess binder (you have to add more to get the strength) during the thermal removal process.

A different paper from Uhland et. al.2 gives a slightly different value, with the assumption of bridging rather than coating.

What are typical yield strengths (tensile strengths) of typical binders? A strong (normal) polymer is in the range of 60MPa. A common binder such as ethyl cellulose is in the range of 40MPa. By adding extra components to a formulation that end up in the polymer, yield strengths will tend to fall. A glance at the literature shows that just 2.5% of a plasticizer can reduce the yield strength by 10-15% so "small" quantities of additives (in terms of the overall formulation) can be "medium" quantities in terms of the polymer binder itself and therefore can give a "large" reduction in yield strength and green strength.

1SJ Lombardo, R Sachanandani, Models of the Strength of Green Ceramic Bodies as a Function of Binder Content and Temperature, pp239-247 in Processing and Properties of Advanced Ceramics and Composites edited by Narottam P Bansal & JP Singh.

2Scott A. Uhlandi et. al., Strength of Green Ceramics with Low Binder Content, J. Am. Ceram. Soc., 84, 2809–18 (2001). Note that Equ 1 and following have an erroneous 1-σ which should be 1-φ.