Corona/Plasma/Flame

Quick Start

The surface energy effects of corona/plasma/flame treatments are irrelevant to adhesion. So what are we really trying to do with them and how, if at all, do they differ?

Although there are plenty of differences between corona, plasma and flame treaters, for the purposes of this page they are considered to be the same. We all know that each of them can be used to improve adhesion to "difficult" surfaces such as polyethylene (PE). What is rather shameful is that for decades everyone has used a classical logical fallacy to explain why these treatments work. It goes like this:

- Nothing sticks to PE

- PE has low surface energy

- Corona/Plasma/Flame increases the surface energy

- The treatments also increase the adhesion

- "Therefore" (and this is the logical fallacy) the adhesion has increased because of the higher surface energy

It should be unnecessary to repeat the reasons why this is a logical fallacy. But the myth that adhesion increases because of increased surface energy refuses to die. So here they are yet again:

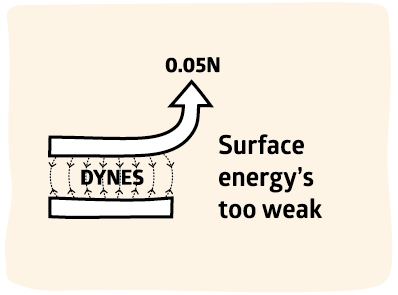

- The increase (from 32-42 dyne/cm) would give from surface energy logic only a 42/32 increase in adhesion, yet the real increases can be orders of magnitude

- 42 dyne/cm is 1000x too small to provide significant practical adhesion

- JKR measurements show that typical surface energy measurements of corona treated PE don't even give the right numbers!

- PET film has the same surface energy as PVC yet it is very hard to stick to PET film

- Amorphous PET has the same surface energy as PET film but is easy to stick to

- Corona treatment of primed PET increases the surface energy but destroys the adhesion by destroying the primer

Another logical mis-step is to ascribe the increase in adhesion to extra surface area (the effect is trivial) or extra functionality (the adhesion increases are large even for inks/coatings that cannot chemically react with the extra functionality).

The real explanation is simple. The treatment "opens up" the crystalline surface of the PE making it more amenable to intermingling/entanglement and also making it more "dissipative". As described in the Adhesibility page this explanation is simple, testable, powerful. If the world of adhesion had put a fraction of the effort wasted on surface energy into performing adhesibility tests using, say, nanoindenters, we'd all be much better off and I wouldn't have to spend so much time explaining why the surface energy explanation is so unhelpful.

Excimer lasers and xenon flashes

Much less well known than corona etc. is the use of excimer lasers or xenon flash exposures (e.g. by 3M and Hoechst) to heat the top few nm of the surface in a super-short time which then cools rapidly to an amorphous state. This gives essentially the same adhesion boost as corona etc. with provably no change in surface functionality - because there are no radical reactions to add hydroxyls, carbonyls etc. Of course this doesn't work for cases where chemical functionality is required (e.g. for adhesion to PEI primers), but it makes the point that a lot or most of the adhesion boosting is from rendering the surfaces amorphous.